CNC machining is a broad term that is commonly used in manufacturing and industry, but what does the acronym CNC stand for?

CNC stands for ‘computer numerical control,’ and CNC machining is a subtractive manufacturing process that typically employs computerized controls and machine accessories to remove layers of matter from a stock piece (known as the blank or workpiece) and create a custom-designed part.

This method is suitable for a wide range of materials, including metals, plastics, wood, glass, foam, and composites, and it is used in a variety of industries, including large CNC machining and CNC machining aerospace components. When it comes to machines, the CNC machine description depicts the original programmable machine capable of autonomously executing CNC machining operations.

CNC machining typically includes two types of services: CNC laser cutting and CNC press bending. We have provided detailed information in this article, including the operation and applications of both of these services.

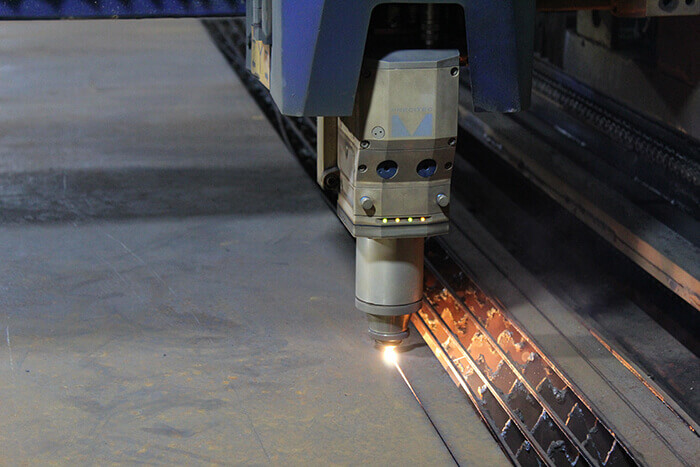

Laser cutting technology is a broad high-tech discipline that combines optical, elements science and engineering, machine manufacturing, digital key technology, electronic technology, and other disciplines. It is currently the focus of universal concern in the science and technology fields, as well as manufacturing circles both at home and abroad. For more than 20 years, laser cutting and application have been rapidly expanding and combining with many methods to form many application fields. Laser cutting, which is essentially a fabrication process, uses a high-powered laser beam to cut various materials into custom shapes and designs. Metal, plastic, wood, gemstone, glass, and paper are among the many materials available.

The primary processing technologies used in laser cutting include laser cutting, laser welding, laser marking, laser drilling, laser heat treatment, rapid laser prototyping, laser coating, and many others. Laser cutting has numerous advantages, including a wide range of cutting, high cutting velocity, a narrow cut, excellent cutting quality, a small heat-affected area, and flexibility. This service is quickly gaining popularity because it produces precise, intricate, and complex parts without the use of or investment in custom-designed tooling. These advantages have a wide range of applications in today’s industry. Laser cutting is now one of the most advanced laser processing technologies.

For optimal use of laser cutting services to perform effectively and at optimum capacity, there are several factors that need to be taken into consideration. Mentioned below are a few factors:

CNC press bending services are an essential part of many manufacturing units because they allow operators to easily work with thick and heavy metals. Its primary goal is to apply tons of weight to solid metal objects, forcing them to change shape to achieve the desired result. Bending a metal sheet at a specific angle is one of the most common applications for CNC press bending services.

Essentially, bending and forming refers to the process of reshaping metals using brake presses and other machine presses. This process is accurate and adjustable with CNC (computerized numerical control) presses. It can be automated using CAD/CAM drawings for increased efficiency and shorter lead times.

The CNC press bending services involves programming the press brake to allow the sheet metal element flat bank at a particularized distance as defined by the point where the structure of the bend will happen.

The press brake clamps the workpiece within a matching die and punch. The sides of the press brake comprise two C-frames connected to a portable beam at the top and a table below. The top tool is installed on the upper shaft, while the bottom is attached to the table.

We, at CEMAR International, provide in-house processing for armored steel and other metal components using CNC machining services like CNC laser cutting services and CNC press bending services. To conduct these services efficiently, we utilize our high-level CNC German laser cutting machines and press bending machines. For more information, or if you are looking to avail of our services, contact us today!